Recent years have been characterised by a strong demand for and commitment to renewable energy. In the Netherlands, this can be seen mainly in the large numbers of solar panels placed on roofs of companies and houses, and in the increase in wind turbines, which some-times seem to shoot up like mushrooms.

These new wind turbines are accompanied by many great developments. For example, they are becoming increasingly efficient, make less noise and sometimes even take into considera-tion the local fauna. Another development is the constant increase in the height of the tur-bines. This particular development presents us with a technical challenge: to build these tur-bines, larger and heavier cranes are required. The Dutch soil, however, remains as weak as ever.

Importance of crane hardstands

Because of the weak soil, a solid design of the crane hardstands is of utmost importance. The crane must stand stable and should not settle or rotate too much. After all, a small rotation will result in a relatively large displacement at the top. Unfortunately, it still frequently hap-pens that hardstands are not stable enough or that they deform too much. As a result, pro-jects are delayed, resulting in financial setbacks that can quickly mount up to tons. This again emphasises the importance of a sound hardstand.

Challenges in the design of crane hardstands

Windbase has long been involved in the design, consultancy and realisation of crane hard-stands and turbine foundations, and has also been involved in the development of the STOWA guideline for the design of crane hardstands. This guideline brings together the different worlds within the wind energy sector; from crane suppliers and geotechnicians to wind turbine manufacturers and project developers. The aforementioned trend has therefore not gone unnoticed within Windbase.

Windbase’s expertise is also regularly called in when a hardstand turns out to be insufficiently stable or shows too much deformations. A quick and robust solution is then required to limit the damage incurred, often in the form of applying a larger mat area under the crane, which increases the load capacity and reduce the deformations. Such a mat area is made of long steel mats which are believed to distribute the crane’s load over a larger surface area. But to what extent is the load from the crane distributed by the mats? And will the full length of the mats or the edges of a larger area of mats transfer the load to the ground? Furthermore, in the design of crane stands, the question has always been whether determining the defor-mations with calculation sheets gives a realistic outcome, given the character and duration of the loads. Isn’t there a method to better deal with this?

Advanced simulations for hardstands

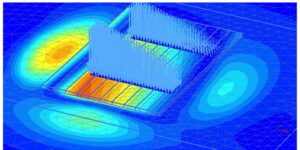

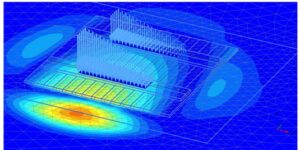

A real-life situation where the aforementioned problems arose was analysed by Windbase by making a PLAXIS 3D model. In this situation, one layer of steel mats was placed under a crawler crane. In this model, the steel mats – with a length of 18 m – were modelled as separate volume elements, with stiffnesses in accordance with the supplier’s data. Subsequently, the load from the crawlers was modelled on the mats. The mats in the model could move separately from each other and were mobilised based the load and the ratio of their own (bending) stiffness to that of the hardstand and further subsoil. After that, a second model was made where the 18 m mats were applied in two layers in order to obtain a better distribution of the loads (see Figure 1). Hereafter, the first model is called ‘model A’ and the second model is called ‘model B’.

As far as the governing situation is concerned, the raising of the crane’s boom was taken. Usually, the hardstand is tested by keeping the boom raised for fifteen minutes, while meas-uring the deformation of the crane. When the crane remains stable, the construction of the turbine can begin. The phases prior to raising the boom are omitted here.

The model showed that the mats are sufficiently stiff to spread the load over the entire length of a mat; of course, the centre of the mat area will transfer most of the load. Under the gov-erning situation it appears that the load in model A is concentrated on a small number of mats (see Figure 2), after which large deformations and failure occur. In model B – because of the 2nd layer of mats – a considerably larger number of mats is mobilised, so that the defor-mations remain smaller and a higher factor of safety is reached (see Figure 3). In principle, these results do not differ from the expectations. In fact, they correspond well with experi-ences from outside with regard to, among other things, the total and differential settlements between loaded and unloaded mats.

Thus, the analyses performed fairly accurately reflect what happens during the operational phase of the hardstands. This makes it possible to calculate the load-bearing capacity and deformations of crane hardstands to a high degree of accuracy, also with regard to the dura-tion of the loads. It remains to be seen if this is possible with the common, traditional calcula-tion tools.

Conclusion and future

Within the wind energy sector, there are many developments. The efficiency and height of the turbines and the size of the cranes are increasing rapidly. It is time to pursue this develop-ment trend within the design of crane hardstands, by means of advanced simulation. Moreo-ver, this method of calculation provides insight into failure mechanisms, the efficiency of mat configurations, and provides input for monitoring plans. It also offers opportunities in the area of integral consultancy services for, and interaction between, the hardstands and turbine foundations, as well as for minimising delays and financial setbacks. As far as Windbase is concerned, there is a bright future for the application of advanced simulations within the world of crane hardstands for wind energy projects!